The Transformative Power of Computer Vision in Modern Industries

Computer vision is revolutionizing industries by enabling machines to “see,” understand, and act on visual data. From optimizing manufacturing lines to enhancing workplace safety, to monitoring transportation infrastructure, AI-powered vision systems are driving efficiency, accuracy, and automation at scale. This technology is not just a futuristic concept; it’s already transforming the way businesses operate today.

1. Automate Sorting

Automated sorting with computer vision is a technology-driven process where computer vision systems identify, classify, and sort items or materials based on specific characteristics like size, shape, color, texture, barcode, or other visual features. For example, defective product sorting, fruit grading, parcel sorting, and pill sorting are all made possible through this innovation. By automating these tasks, businesses can reduce labor costs and improve efficiency.

2. Count Objects

Detecting and counting objects on a conveyor belt using computer vision is a game-changer for many industries. In manufacturing environments, conveyor belts transport small components such as bolts, nuts, or other fasteners through various stages of production. Real-time object counting improves inventory management, quality assurance, and overall efficiency.

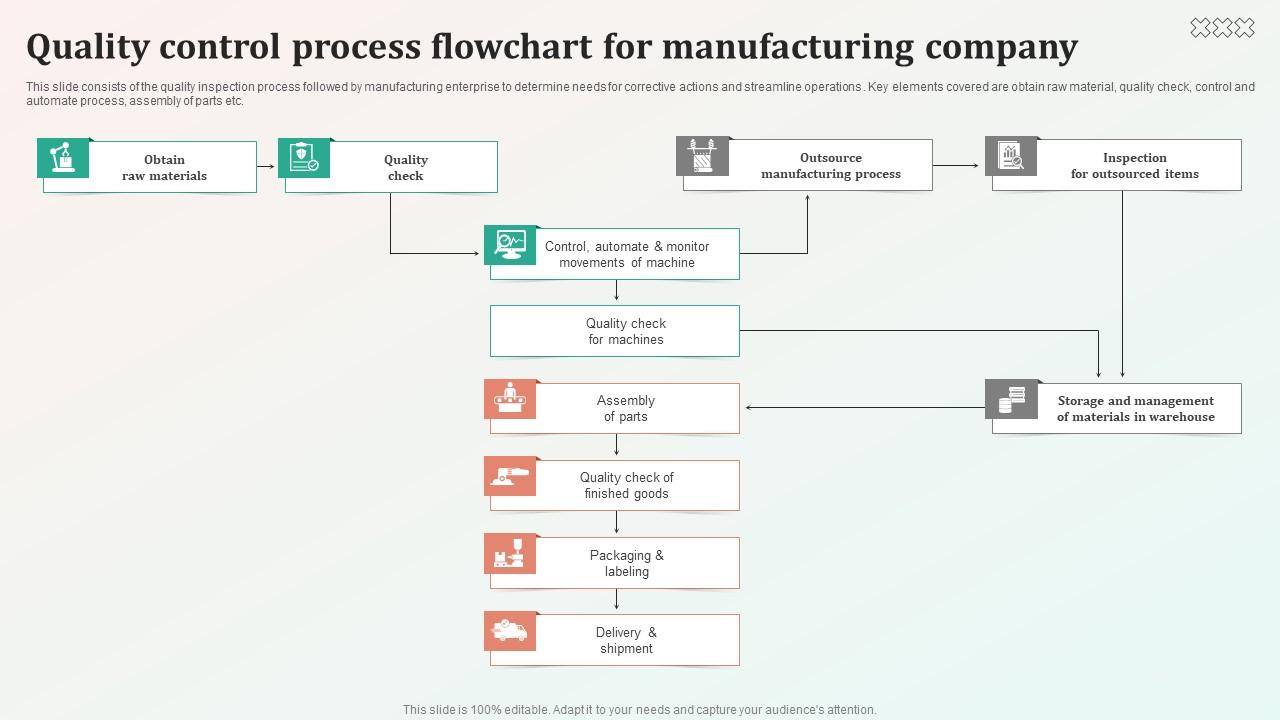

3. Quality Control

With computer vision, you can detect any defects visible to a camera—such as nuanced variations in product specifications like color, texture, inaccurate labels, and other slight imperfections. When a defect is detected, automated systems can remove the product from an assembly line. This ensures that only high-quality products reach consumers.

4. Avoid Jams

An AI-assisted monitoring system can help avoid costly pileups. Computer vision can continuously track goods moving along the production line and identify when a component is the wrong size or angled incorrectly. When a problem is detected, it can trigger an alarm for production crews to resolve the issue proactively.

5. Predictive Maintenance

Regular maintenance is vital to improving any product’s lifetime. By regularly monitoring costly equipment for cracks, changes, rust, and missing pieces, manufacturers can prevent unexpected breakdowns and avoid disruptions in operations. This predictive approach saves time and money while ensuring consistent performance.

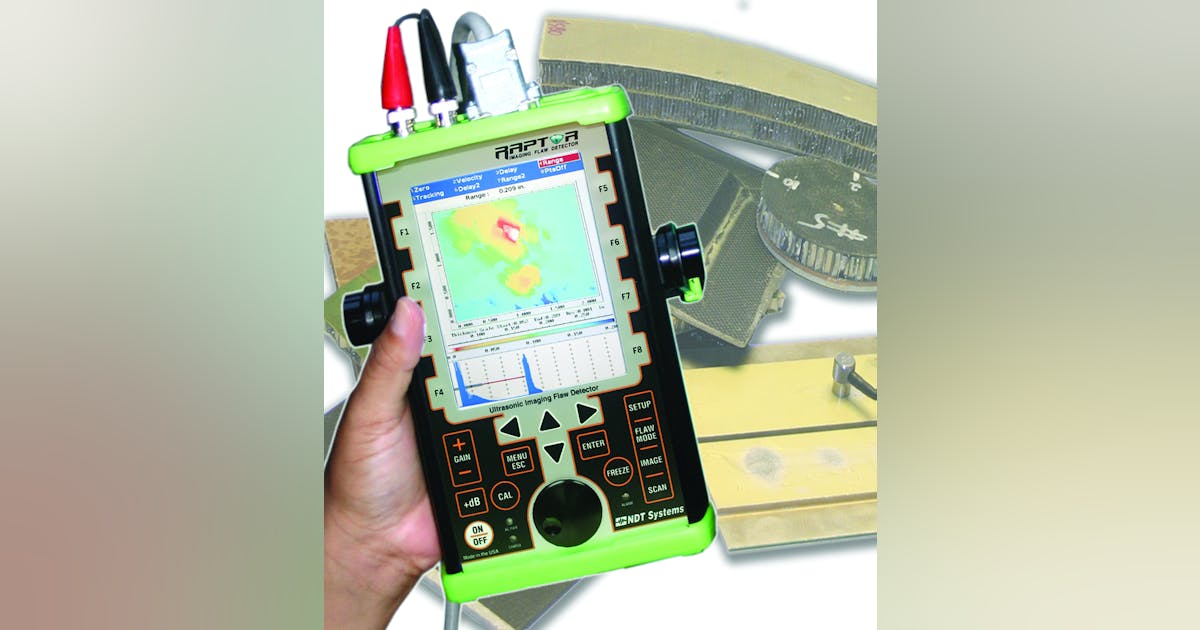

6. Flaw Detection

Flaw detection can be used to detect a wide range of defects, including surface defects, structural issues, and material inconsistencies. Surface defects, such as scratches, dents, or blemishes, are visible on the product’s exterior. On the other hand, structural issues, like cracks or delaminations, may be internal and require more advanced inspection techniques. Computer vision systems can quickly process large amounts of data and shorten inspection times.

7. Workplace Safety

Analyzing and detecting when a person falls with computer vision is crucial in manufacturing facilities, where a fall may present a significant danger to ongoing operations. Computer vision can distinguish between what is likely to be a fall versus someone kneeling and other voluntary acts that involve being in a non-standing position.

8. Zone Monitoring

One potential use of computer vision is to identify when people enter a restricted zone. This can be used to monitor entry into a zone and count the number of people present to ensure the zone does not get too crowded. This application is particularly useful in public spaces and industrial settings.

9. Inspect Labels

Label inspection is used on assembly lines, packaging plants, or other industrial environments (such as food and beverage, pharmaceuticals, and manufacturing), where accurate labeling is crucial for compliance, traceability, and customer satisfaction. Computer vision for label inspection can include ensuring that a label is present on the product, confirming the label is placed in the correct position, and detecting misaligned labels.

10. Alignment Detection

Checking an object’s alignment involves making sure it is exactly where it needs to be, and in the correct position and direction. An object’s alignment and position can require high levels of precision in various fields. For example, in manufacturing, even a small misalignment can cause defects. Computer vision can be used to detect 2D and 3D alignment.

11. Automated Color Sensing

Automated color detection is more important in our daily lives than we might realize. For instance, it helps factories make sure products look just right by checking for color differences. In cars, it assists with parking and staying in the correct lane. Even your smartphone uses color detection to make photos look better and apply cool filters. With computer vision, you can identify the main colors of an object in an image.

12. Autonomous Drones

UPS Supply Chain Solutions is tracking inventory via autonomous drones. The distribution location where the drones rolled out has a 266,000-square-foot storage area and manages over 930,000 inventory movements annually. The number of hours spent on inventory processes is already down by half at the UPS site.

13. Read Paper Receipts

Using vision AI models, you can take a photo of a receipt and ask questions to retrieve specific information about a receipt (i.e., how much was spent on a single item); retrieve all text in a receipt; calculate how much tax was added onto a transaction, and more. This application streamlines financial management for businesses.

14. Read Invoices

Using models like GPT or Gemini, you can read the text of an invoice and retrieve it as plain text. This information can then be used in business logic. For example, you could build a tool that takes a screenshot of PDF invoices and retrieves specific information, or a tool for digitizing old invoices.

15. Extract Nutrition Data from Food Labels

Accurate nutrition data extraction from food labels is difficult due to the variability of label information, size of labels, and current vision model capabilities. Traditional Optical Character Recognition tools struggle with the complexity and variability of food labels, but Vision Language Models like GPT-4o offer a powerful, context-aware solution.

16. Create a Retail Planogram

Retail planograms can help ensure every precise detail in a store’s layout according to business requirements. By leveraging the use of planograms, retailers can ensure compliance with vendor agreements, measure the effectiveness of price changes, product offers, and more. By leveraging computer vision technologies, retailers and vendors can automate the creation of dynamic and scalable planograms.

17. Automatic Stop Sign Violation Detection

This automatic stop sign violation detector utilizes an object detection model fine-tuned in Roboflow, combined with Roboflow’s PolygonZone to identify vehicles that violate stop signs. Video recordings of vehicles that fail to stop are flagged for reporting.

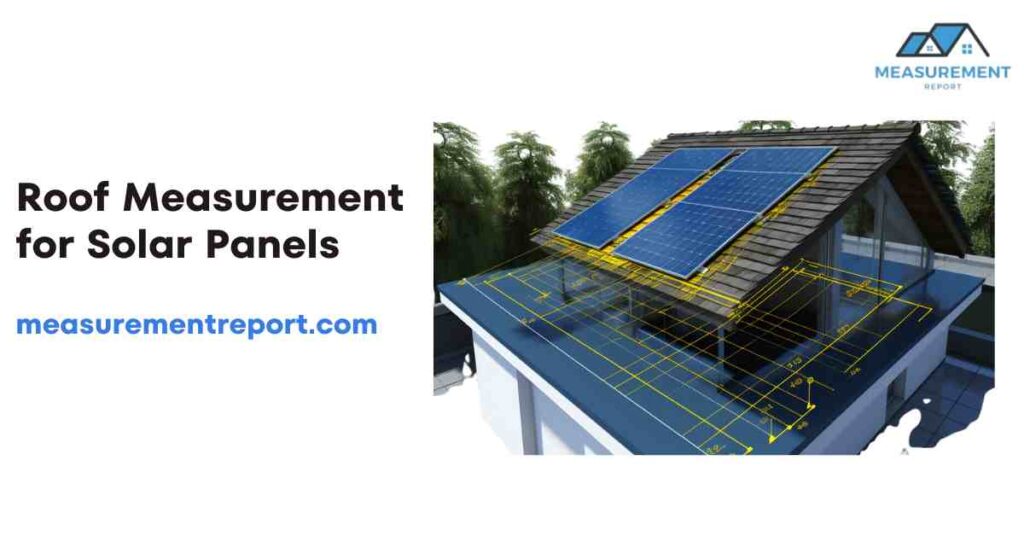

18. Solar Roof Measurement

For solar businesses and installers, accurately estimating the roof surface area is crucial for planning, costing, and optimizing the number of solar panels that can be installed on a specific house. Traditional methods of roof measurement can be time-consuming and labor-intensive. However, with advancements in computer vision and the availability of high-resolution aerial imagery, it’s now possible to automate this process efficiently.

19. Agricultural Robots

Vision-enabled robots are used to monitor plant growth, complete harvest tasks, and more. Machines like LaserWeeder are widely used in countries like North America, Europe, and Australia, harnessing computer vision and deep learning to identify and eliminate weeds from croplands.

20. Self-Driving Cars

Autonomous cars come equipped with advanced driver assistance systems that use computer vision to improve the driving experience. Tesla’s autopilot system consists of eight vision cameras that process 360-degree vision for up to 250 meters. Based on the data gathered from these eight cameras, the hardware can analyze real-world information and detect pedestrians, lanes, and road signs.

Conclusion

Computer vision is transforming industries by automating complex visual tasks, improving efficiency, and reducing errors. From streamlining aerospace operations to quickly verifying government documents, and even automating security procedures for oil rigs, the many uses of vision AI continue to expand. With accessible tools and pre-trained models, businesses can now integrate computer vision into their workflows faster than ever. As you’ve seen, the right vision AI solutions can drive significant improvements in cost, speed, and accuracy.